1. What’s opening and mesh count

A:Opening identifies the open area between the parallel wires.

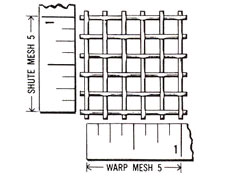

B:Mesh Count identified as the number of openings per linear inch

Mesh count can be shown as either a whole number, fraction, or as two numbers unless the material is a specialty cloth called space cloth - each item is described below:

Whole Number or Fraction

Mesh Count is identified as the distance from center to center of the parallel wires horizontally and vertically.

Space Cloth

This material is measured by the actual open space between parallel wires, known as clear opening, space size, or open area.

Two Numbers (Example: 2 x 2 )

Mesh Count is identified by the number of actual openings per linear inch horizontally and vertically.

2. Mesh Calculation:

Mesh count = 25.4mm / (wire diameter + opening)

Wire diameter= 25.4mm/mesh count-opening

Opening=25.4mm/mesh count-wire diameter

Open area = opening x opening/(wire diameter + opening)² x 100%

3.How to Measure Wire Cloth:

Coarse Mesh

To measure wire cloth (woven wire cloth, stainless steel wire cloth, wire cloth screen, wire cloth strainer, industrial wire cloth, metal cloth, wire cloth) properly, the mesh count should be taken in both directions. On coarse meshes (mesh wire, woven wire mesh, wire mesh basket), this can be accomplished by counting the number of openings per linear inch measuring from wire center to wire center. After taking the first count, a second count should be taken at a 90 degree angle to the original measurement. The mesh count of the cloth shown is 10x10.

Fine Mesh

A mesh counter is used to measure finer meshes of wire cloth (woven wire cloth, stainless steel wire cloth, wire cloth screen, wire cloth strainer, industrial wire cloth, metal cloth, wire cloth) accurately. The fine mesh count is taken the same way the coarse mesh is computed by counting the number of openings per linear inch in one direction and taking another count at right angles to the original measurement.

Wire Diameter

Wire diameter is always checked with a micrometer. Diameters of wires in both directions should be checked.

For more information, please kindly contact with us directly.

PREVIOUS: The best printing time after stretching